ATEX Coding

To meet the exacting requirements of ATEX directive 2014/34/EU, Peli Lights are tested to ensure that they pose no threat of ignition when operating within hazardous locations. Using approved laboratories, the lights are tested to ensure that they will withstand rigorous impact and drop tests, severe environmental exposure and meet a minimum of IP54 water and dust ingress protection. Longevity and safety are assured by design. Lights with gas approvals do not require impact test and gas approval only requires IPX4 (gas approval does not require dust test IP5X. Dust approval requires IP6X dust test).

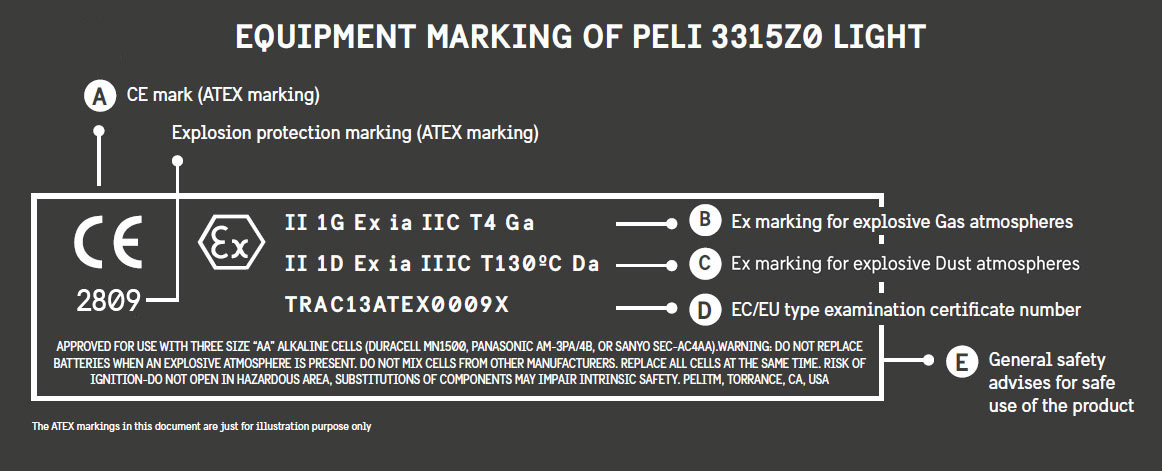

Each light certified by ATEX should have a code printed on its body. This code advises the user as to the zone in which it can be safely used without risk of explosion.

ATEX Marking for Mining

| I | M1 | Ex | ia | I | Ma |

| I | Equipment Group | Approved for mining |

| MIMII | Equipment Category and Environment |

2 levels of protection/2 independent faults 1 level of protection/based on normal operation |

| Ex | Specific Marking | Explosion protection |

| ia/ib | Type of protection | Intrinisic safety level of the device in Zone 0/1 |

| I | * Gas Group | Methane |

| Ma/Mb | Equipment Protection Level | High, safe with 2 faults/high, safe with 1 fault |

ATEX Marking for Gas

| II | 1G | Ex | ia | IIC | T4 | Ga |

| I II |

Equipment Group |

Approved for mining No mining |

| 1G 2G 3G |

Equipment Category and Environment |

Category 1, use in Zone 0/1/2 Category 2, use in Zone 1/2 Category 3, use in Zone 2 |

| Ex | Specific Marking | Explosion protection |

| ia/ib/ic | Type of protection | Intrinisic safety level of the device in Zone 0/1/2 |

| IIA IIB IIC |

* Gas Group |

i.e. Propane i.e. Ethylene i.e. Hydrogen |

| T1/T2/T3 T4/T5/T6 |

* Temperature Class |

Maximum surface temperature of 450°C/300°C/200°C Maximum surface temperature of 135°C/100°C/85°C |

| Ga/Gb/Gc | Equipment Protection Level | High, safe with 2 faults/high, safe with 1 fault |

ATEX Marking for Dust

| II | 1D | Ex | ia | IIIC | T130°C | Da |

| I II |

Equipment Group |

Approved for mining No mining |

| ID IID IIID |

Equipment Category and Environment |

Category 1, use in Zone 20/21/22 Category 2, use in Zone 21/22 Category 3, use in Zone 22 |

| Ex | Specific Marking | Explosion protection |

| ia/ib/ic | Type of protection | Intrinisic safety level of the device in Zone 0/1/2 |

| IIA IIB IIC |

* Dust Group |

i.e. Flammable Fibres i.e. Non conductive dust i.e. Conductive dust |

| T | * Temperature Class | Maximum surface temperature level is to be indicated |

| Da/Db/Dc | Equipment Protection Level | High, safe with 2 faults/high, safe with 1 fault |

* Temperature Class

| Temperature Class | Ignition Temperature | Examples |

| T1 | ≥ 450 °C | Propane, lighting gas, hydrogen |

| T2 | ≥ 300 °C | Ethyl alcohol, Ethylene, Acetylene |

| T3 | ≥ 200 °C | Fuel |

| T4 | ≥ 135 °C | Acetaldehyde |

| T5 | ≥ 100 °C | Hydroxylamine |

| T6 | ≥ 85 °C | Carbon disulfide |

- The Auto-Ignition Temperature is the temperature, in C at which a gas will ignite spontaneously without another source of ignition

- Because there is NO correlation between Ignition Energy and Ignition Temperature for the gas groupings, a temperature code was established

- The Temperature Class is based on use in an ambient temperature of -20/40 C. If the ambient temperature differes from that range, it needs to be shown.

* Gas Group

| Industry | Gas Group | Substance | Minimum Ignition Energy | Selection of Equipment |

|

Mining Industry Group I |

I | Metahne | 200 µJ | For mines susceptible to methane |

|

Surface Industry Group II |

IIA IIB IIC |

Propane Ethylene Hydrogen |

180 µJ+ 60 - 180 µJ 20 - 60 µJ |

Atmospheres containing propane/butane/oil/ammonia Atmosphere containing ethylene/ether Atmosphere containing hydrogen/acetylene |

- Gases are divided into two groups based on the LEL and UEL values.

* Dust Group

| Dust Group | Substance | Selection of Equipment | Examples |

| IIIA | Flammable fibers > 0,5mm | Explosive surface > 1000 hrs/yr | Wood shaving |

| IIIB | Non-conductive dust with electrical resistivity > 103 Ωm | Explosive surface between 10 and 1000 hrs/yr | Saw dust, flour |

| IIIC | Conductive dust with electrical resistivity ≤ 103 Ωm | Explosive surface less than 10 hrs/yr | Metal dust |

- Dust areas are defined as group III and refers to equipment intended for use in spaces with an explosive dust atmosphere other than mines susceptible to firedamp.

Maximum Surface Temperature

Group III electrical equipment is marked with a temperature with ‘T’ prefix detailing the actual maximum temperature that may be found on any surface accessible by a potentially explosive dust atmosphere. Ignition temperature of a specific dust hazard must be higher than maximum surface temperature displayed on electrical equipment.

Ignition Temperatures for Common Combustible Dusts

| Dust Type | Dust Group |

Dust Layer (5mm) Minimum Ignition Temperature (°C) |

Dust Cloud (5mm) Minimum Ignition Temperature (°C) |

| Aluminum | IIIC | 450 | 560 |

| Blasting Dust (Paint Shreds) | IIIB | 270 | 390 |

| Coal | IIIB | 380 | 560 |

| Flour (Wheat) | IIIB | 450 | 430 |

| Grain | IIIA | 290 | 490 |

| Iron Powder | IIIC | 450 | 520 |

| Paper Fibre | IIIA | 335 | 470 |

| PVC | IIIB | 440 | 680 |

| Resin (Epoxy) | IIIB | 240 | 532 |

| Rubber | IIIB | 450 | 470 |

| Soot | IIIB | 450 | 720 |

| Starch (Maize) | IIIB | 490 | 430 |

| Sugar | IIIB | 460 | 360 |

| Wood (Flour) | IIIB | 305 | 470 |

EC/EU Type Examination Certificate Number

| TRAC | 13 | ATEX | 0009 | X |

| Notified body responsible for EC/EU-Type Examination | Year Issued | ATEX Certificate | Serial Number | Number Suffix |